Izici:

1. Ukumelana kahle kwe-shear

2. Izinga lokushisa lokumelana ne-soldering ngu-288℃

3. Ukuzinza kwamakhemikhali okuhle kakhulu,

4. Ukumelana nemisebe,

5. Ukumelana ne-Chemical solvent kanye ne-anti-corrosion

6. Kulula ukufa-ukusika kunoma yimuphi umklamo womumo wangokwezifiso

7. Ukufakwa kukagesi okusezingeni eliphezulu

8. Ingcina ye-thermosetting

9. Isiphetho esibushelelezi, awekho amabhamuza kanye ne-delamination

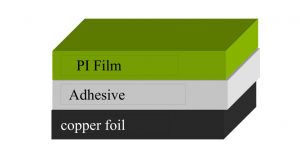

Ibhodi lesifunda le-FPC eliguquguqukayo livamise ukuboshelwa nge-adhesive thermosettingifilimufuthii-polyimide stiffeneripuleti.I-adhesive thermosettingifilimuis ngaphandle viscosity ngenkathiokuqinile ekushiseni okuvamile, kodwa lapho izinga lokushisa likhuphuka liye kwelinyeububanzi, izoshintsha ibe yisimo esiqinile esine-viscosity eqinile.Ngalesi sikhathi, i-FPC izonamathela ku-i-polyimide stiffeneripuleti.Umkhuba ojwayelekile uwukuhlanganisa iI-PI stiffener fanele kwesokudlaisikhundla, futhi usebenzise ugesii-solderingiron for 1 ~ 2 imizuzwana ukuzelungisa iiphuzu elilodwa isikhundlan.Ngemuva kokushisa okuphezulu nokucindezela okuphezuluing, yonke indawokungabaukuhlangana ngokuphelele,beseukubhakaifilimu ukwelapha ingcina.

Isimo sokucutshungulwa kwefilimu ye-copper clad polyimide noma ishidi le-polyimide stiffener:

1. Ibhendi yokuqala: izinga lokushisa ngu-120℃, ukucindezela okuphezulu okungu-20kg/ cm², 1min;

2. Ibhendi yesibili: izinga lokushisa 140℃, ukucindezela okuphezulu 30kg/ cm², 80min;

3. Ibhendi yesithathu: izinga lokushisa 80℃,ingcindezi ephezulu 30kg/cm², 5min;

Isicelo:

Ukuhlanganiswa kwebhodi le-FPC

PCB Board yokukhiqiza

I-Coverlay noma i-Stiffener ku-F-PCB.

Umhlangano webhodi lesifunda sezimoto

Transformer kanye Motor Insulation.

-

Ifilimu ye-PTFE teflon ekwazi ukumelana nokushisa kwe-elec...

-

Die Cutting Nomex Insulation Paper Nomex 410 fo...

-

Itheyiphu Engazweli Ngamazinga Okushisa Ephezulu ye...

-

Indwangu Yengilazi PTFE Teflon Adhesive Tape for High ...

-

I-Double Side Kapton Tape ye-Electronic Componen...

-

I-Poylimide Sublimation Heat Transfer Tape yeSu...