Iimbonakalo:

1. Ukumelana kakuhle nokucheba

2. Ubushushu bokumelana ne-Soldering yi-288℃

3. Uzinzo olugqwesileyo lweekhemikhali,

4. Ukumelana nemitha,

5. Ukumelana ne-Chemical solvent kunye ne-anti-corrosion

6. Kulula ukufa-ukunqunyulwa kulo naluphi na uyilo lwemilo yesiko

7. Ukufakwa kombane okumgangatho ophezulu

8. I-adhesive ye-thermosetting

9. Ukugqiba okugudileyo, akukho amaqamza kunye nokuncipha

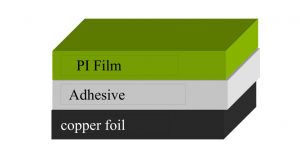

Ibhodi yesekethe ye-FPC eguquguqukayo idla ngokudityaniswa ne-adhesive thermosettingifilimukwayepolyimide stiffeneripleyiti.I-adhesive thermosettingifilimuis ngaphandle viscosity ngelixaiqinile kwiqondo lobushushu eliqhelekileyo, kodwa xa ubushushu bonyuka busiya kwiqondo elithileuluhlu, iya kutshintsha ibe yi-semi-solidified state kunye ne-viscosity eqinile.Ngeli xesha, i-FPC iya kunamathela kwipolyimide stiffeneripleyiti.Inkqubo jikelele kukulungelelanisaI-PI stiffener kufanelekile ekuneneisikhundla, kwaye usebenzise umbanei-solderingiron for 1 ~ 2 imizuzwana ukuyalungisa iindawo enyen.Emva kokushisa okuphezulu kunye noxinzelelo oluphezulunge, wonke umphezuluiza kubayiukudibanisa ngokupheleleyo,ngokoukubhakaifilimu ukunyanga i-adhesive.

Imeko yokusetyenzwa kwefilimu yepolyimide eyenziwe ngobhedu okanye iphepha le-polyimide stiffener:

1. Ibhendi yokuqala: iqondo lobushushu 120℃, uxinzelelo oluphezulu 20kg/ cm², 1min;

2. Ibhendi yesibini: iqondo lobushushu 140℃, uxinzelelo oluphezulu 30kg/ cm², 80min;

3. Ibhendi yesithathu: iqondo lobushushu 80℃, uxinzelelo oluphezulu 30kg/ cm², 5min;

Isicelo:

Indibano yebhodi yeFPC

PCB Board ukwenziwa

I-Coverlay okanye i-Stiffener kwi-F-PCB.

Indibano yebhodi yesekethe yeemoto

ITransformer kunye neMotor Insulation.

-

Skived ukumelana nobushushu PTFE teflon Film ye elec...

-

Die Cutting Nomex Insulation Paper Nomex 410 fo...

-

Iteyiphu yokuNgena koBuqondo obuPhezulu obuFana ne...

-

Ilaphu leglasi PTFE Teflon Adhesive Tape for High ...

-

ITape yeKapton yecala eliphindwe kabini yeComponen ye-Electronic...

-

I-Poylimide iTape yokuTshintshela ubushushu beSu...