Mawonekedwe:

1. Kukana kukameta ubweya wabwino

2. Kutentha kwa kutentha kwa kutentha ndi 288 ℃

3. Kukhazikika kwamphamvu kwamankhwala,

4. Kukana kwa radiation,

5. Chemical zosungunulira kukana ndi odana ndi dzimbiri

6. Zosavuta kufa-kudula mumapangidwe amtundu uliwonse

7. Kutsekemera kwamagetsi kwapamwamba

8. Thermosetting zomatira

9. Mapeto osalala, opanda thovu ndi delamination

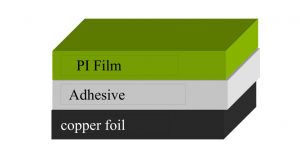

FPC flexible circuit board nthawi zambiri imamangiriridwa ndi zomatira za thermosettingkanemandipolyimide stiffenermbale.Thermosetting zomatirakanemais popanda mamasukidwe akayendedwecholimba pa kutentha kwabwino, koma kutentha kukakwera kufika pamlingo winaosiyanasiyana, izo zidzasintha kukhala theka-okhazikika boma ndi mamasukidwe akayendedwe amphamvu.Panthawiyi, FPC idzamamatira kupolyimide stiffenermbale.Mchitidwe ambiri ndi agwirizane ndiPI stiffener oyenera kumanjaudindo, ndi ntchito magetsisolderingchitsulo kwa 1 ~ 2 masekondi kutikonzasingle point position.Pambuyo pa kutentha kwakukulu ndi kusindikiza kwakukulundi, padziko lonseadzakhalakugwirizana kwathunthu,ndiyekuphikafilimu kuchiritsa zomatira.

Kukonzekera kwa filimu yamkuwa ya polyimide kapena pepala la polyimide stiffener:

1. Gulu loyamba: kutentha 120 ℃, kuthamanga kwambiri 20kg/cm², 1min;

2. Gulu lachiwiri: kutentha 140 ℃, kuthamanga kwambiri 30kg/cm², 80min;

3. Gulu lachitatu: kutentha 80 ℃, kuthamanga kwa 30kg/cm², 5min;

Ntchito:

Chithunzi cha FPC

PCB Board kupanga

Coverlay kapena Stiffener mu F-PCB.

Msonkhano wa komiti yoyendera magalimoto

Transformer ndi Motor Insulation.

-

Skived kutentha kugonjetsedwa PTFE teflon Kanema wa elec...

-

Die Cutting Nomex Insulation Paper Nomex 410 fo...

-

Tepi ya High Temperature Resistant Sublimation ya...

-

Chovala cha Galasi PTFE Teflon Adhesive Tepi Yapamwamba ...

-

Tepi Yapawiri Yapawiri ya Kapton ya Electronic Componen...

-

Tepi ya Poylimide Sublimation Heat Transfer ya Su...