Rogers Bisco HT-6000 Firmus Silicone pro Gasketing et Obsignando

Features

1. Praesto crassitudines ab 0.010 ad 0.125 in

2. valde stricta tolerances crassitudine

3. Durometer of 10-65 Shore A ad arbitrium

4. Minimum Compressionis paro (<5%)

5. Tensile robur 250 ad 1000 PSI

6. Prolongatio 175 ad 650%

7. Resistentia Verone 25-125 PPI

8. HT-6210 mollis est extra, HT-6220 est mollis gradus

9. HT-6135 stricta est tolerantia, HT-6240 solida silicone perspicua

10. HT-6360 est firesafe gradus solidi silicone

Applicatio:

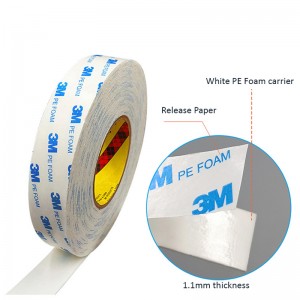

Rogers Bisco HT 6000 series solida materiae siliconis habet egregias lineamenta caliditatis resistentiae, resistentiae UV et Ozone, et adhiberi possunt ut gaskets, scuta caloris, sealants, et pulvinaria, insulatio caloris in variis industriis, sicut conventus autocineti, machinae industriae; constructio industria, conventus industriae electronic, etc. Bisco solidae materiae silicones laminari possunt cum 3M taenia adhaesiva, sicut 3M 467/468MP, 3M 9495LE, et mori in varias formas sicut ligamenta, partes circuli quadratae partes in usu in applicatione facile uti.

Ut taeniolae adhaesivae convertentis professionalis, GBS non solum notam nostram adhaesivam taenia fabricat, sed etiam officia convertendo praebet ad alias materias notas sicut materiam solidam Silicone Rogers Bisco, Rogers Poron materiae, etc.

Nobis loquereut solutionem tuam domicilii tui!

Industria servivit:

* Interior & exterior conventus

* Adhibetur signare, gasketing, cushioning et calor protegens pro variis industries

*LCD&FPC Fixing

* Pro signandis et gasketing partium electronicarum et machinarum electronicarum

* Praesidium et gap ostentationem saturitatem

* Pugna pads et cushioning

* Alia industria quae indigent gasketing et obsignando

| Rogers Bisco HT-6000series Firmus Silicone Technical Data Sheet | ||||||

| Property | Test Methodi | HT-6210 | HT-6220 | HT-6135 | HT-6240 | HT-6360 |

| Crassitudo range (mm, inch) | Internum | 0.25-3.18mm (0.01-0.125in) | 0.25-3.18mm (0.013-0.125in) | 0.25-1.59mm (0.013-0.063in) | 0.25-3.18mm (0.01-0.125in) | 0.5-3.18mm (0.02-0.125in) |

| Color | Visual | Gray | nigreos | Crepito | Perspicuus | nigreos |

| Gravitas specifica (g/cc) | Internum | 1.07 | 1.08 | 1.22 | 1.07 | 1.71 |

| Durometer Shore OO | ASTM D2240 | 10 | 20 | 33 | 41 | 63 |

| Cogo Set (%) | ASTM D395 150℃/22hour | 25 | 25 | 25 | 35 | 35 |

| Distrahentes fortitudo (MPA,psi) | ASTM D412 | 3.3Mpa 480psi | 4.4Mpa 640psi | 4.4Mpa 640psi | 7.17Mpa 1040psi | 1.72Mpa 250psi |

| Prolongatio (%) | ASTM D412 | 565% | 580% | 580% | 325% | 125% |

| Lacrime resistentia, ppi | ASTM D624 | >20 | 116 | 116 | 112 | |

| Dielectrica fortitudo, Volts/mil | ASTM D149 | 372 | 374 | 381 | 386 | 386 |

| Dielectrc Constant, 1kHz | ASTM D150 | 2.76 | 2.97 | 2.95 | 2.76 | 2.76 |

| Dissipatio Factor, 1kHz | ASTM D495 | 0.003 | 0.003 | 0.001 | 0.003 | 0.003 |

| Arcus Resistentia arida, Secundi | ASTM D495 | 122 | 123 | 145 | 124 | 124 |

| Volumen Resisivity, Ohm-cm | ASTM D257 | 10^14 | 10^14 | 10^14 | 10^14 | 10^14 |

-

Medium Firmness Silicone Foam Rogers Bisco HT-800

-

3M 300LSE Adhesive 9495LE/9495MP Duplex Sided P...

-

Die Cutting Nomex Insulation Paper Nomex 410 fo...

-

Dissecans 3M VHB series 4910 4941 4611 5952 F.

-

Duplex Coated 3M 1600T PE Foam Tape pro Generali...

-

Custom Converting Full Series of Spuma Tape Roge...