atụmatụ:

1. Ezigbo iguzogide ihe

2. soldering eguzogide okpomọkụ bụ 288 ℃

3. Magburu onwe chemical kwụsie ike,

4. Nguzogide radieshon,

5. Chemical mgbaze eguzogide na mgbochi corrosion

6. Ọ dị mfe ịnwụ na-egbutu n'ụdị ọdịdị omenala ọ bụla

7. Igwe ọkụ eletrik dị elu

8. Thermosetting nrapado

9. Ngwunye dị nro, enweghị afụ na delamination

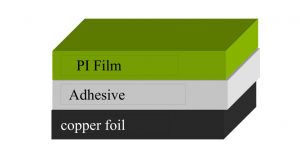

A na-ejikọ bọọdụ sekit na-agbanwe agbanwe FPC na nrapado thermosettingihe nkirinapolyimide siri ikeefere.The thermosetting nrapadoihe nkiriis na-enweghị viscosity mgbesiri ike na okpomọkụ nkịtị, ma mgbe okpomọkụ na-ebili na ụfọdụoke, ọ ga-agbanwe n'ime ọkara siri ike nke nwere viscosity siri ike.N'oge a, FPC ga-arapara na yapolyimide siri ikeefere.Omume n'ozuzu bụ ịkwado nkePI siri ike dabara na aka nriọnọdụ, ma jiri ọkụ eletrikire ereígwè maka 1 ~ 2 sekọnd kadozie nkeotu ebe position.Mgbe elu okpomọkụ na elu pịaing, elu dumga-abụnjikọ zuru oke,mgbe ahụime achịchaihe nkiri ahụ iji gwọọ nrapado.

Ọnọdụ nhazi nke ihe nkiri polyimide ọla kọpa ma ọ bụ mpempe akwụkwọ stiffener polyimide:

1. Nke mbụ band: okpomọkụ 120 ℃, elu mgbali 20kg / cm², 1min;

2. Nke abụọ gbalaga: okpomọkụ 140 ℃, elu mgbali 30kg / cm², 80min;

3. Nke atọ gbalaga: okpomọkụ 80 ℃, elu mgbali 30kg / cm², 5min;

Ngwa:

Mgbakọ bọọdụ FPC

PCB Board nrụpụta

Mkpuchi ma ọ bụ Stiffener na F-PCB.

Mgbakọ bọọdụ ụgbọ ala

Transformer na moto mkpuchi.

-

Skived okpomọkụ na-eguzogide PTFE teflon Film maka elec ...

-

Die Cutting Nomex Insulation Paper Nomex 410 fo...

-

teepu Sublimation na-eguzogide oke okpomọkụ maka...

-

Glass Cloth PTFE Teflon nrapado teepu maka elu ...

-

teepu Kapton akụkụ okpukpu abụọ maka akụrụngwa eletrọnịkị...

-

Ihe nfefe ọkụ nke Poylimide Sublimation maka Su...