Nta:

1. Zoo shear kuj

2. Soldering kuj kub yog 288 ℃

3. Zoo heev tshuaj stability,

4. Kev tiv thaiv hluav taws xob,

5. Tshuaj hnyav ua haujlwm thiab tiv thaiv corrosion

6. Yooj yim rau tuag-txiav nyob rau hauv tej kev cai zoo tsim

7. High class hluav taws xob rwb thaiv tsev

8. Thermosetting nplaum

9. Smooth tiav, tsis muaj npuas thiab delamination

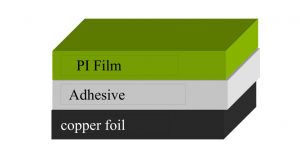

FPC yooj ywm Circuit Court board feem ntau yog sib txuas nrog thermosetting nplaumzaj duab xisthiabpolyimide stiffenerphaj.Thermosetting nplaumzaj duab xisis tsis muaj viscosity thaumkhoom ntawm qhov kub thiab txias, tab sis thaum kub nce mus rau ib qhontau, nws yuav hloov mus rau hauv ib lub xeev semi-solidified nrog muaj zog viscosity.Lub sijhawm no, FPC yuav lo rau ntawmpolyimide stiffenerphaj.Kev xyaum dav dav yog los ua kom haumPI khoom haum rau txoj caitxoj hauj lwm, thiab siv hluav taws xobsolderinghlau rau 1 ~ 2 vib nas thiskho covib qho point position.Tom qab kub kub thiab siab xovxwmhauv, tag nrho saum npooyuav yogkev sib raug zoo tag nrho,cescizaj duab xis los kho cov nplaum.

Kev ua haujlwm ntawm tooj liab clad polyimide zaj duab xis lossis polyimide stiffener ntawv:

1. Thawj pawg: kub 120 ℃, siab siab 20kg / cm², 1min;

2. Qhov thib ob band: kub 140 ℃, siab siab 30kg / cm², 80min;

3. Qhov thib peb band: kub 80 ℃, siab siab 30kg / cm², 5min;

Daim ntawv thov:

FPC pawg thawj coj saib

PCB Board tsim

Coverlay lossis Stiffener hauv F-PCB.

Automotive circuit board sib dhos

Transformer thiab Motor Insulation.

-

Skived tshav kub resistant PTFE teflon Zaj duab xis rau elec ...

-

Tuag txiav Nomex rwb thaiv tsev ntawv Nomex 410 fo ...

-

High Temperature Resistant Sublimation Daim kab xev rau ...

-

Iav Cloth PTFE Teflon Adhesive Daim kab xev rau High ...

-

Ob chav Sab Kapton Daim kab xev rau Electronic Componen ...

-

Poylimide Sublimation Thaum tshav kub kub hloov daim kab xev rau Su ...