Comprehensive Performance PET Film for Thermal Transfer and Printing Industries

Features

1. High Strength and Heat Resistance: It can withstand temperatures exceeding 220°C.

2. Lightweight and High Rigidity: Suitable for honeycomb structures that require both strength and lightweight properties.

3. Excellent Thermal and Sound Insulation: Its microporous structure provides excellent thermal insulation and soundproofing, making it ideal for applications requiring heat isolation.

4. Corrosion Resistance and Chemical Stability: It maintains stability in harsh environments.

5. Flame Retardant and Excellent Electrical Insulation Properties: The breakdown voltage can reach 40KV/mm.

6. Excellent radiation resistance. With resistance to α, β, χ-ray and ultraviolet radiation.

Advantages in Honeycomb Core Applications:

1. High Strength-to-Weight Ratio: As a honeycomb core material, it provides both strength and structural integrity while maintaining a lightweight form, making it highly suitable for industries such as aerospace, automotive, and military.

2. High-Temperature and Impact Resistance: It can withstand extreme temperatures and effectively absorb shock, making it ideal for applications that need impact resistance and high-temperature endurance.

3. Environmental Friendliness: Aramid paper is recyclable and has a lower environmental impact

|

Name |

Aramid paper |

|

Model |

GBS-FW827 |

| Nominal ThicknessFlame rating | 0.13 (mm)V-0,5VA |

| Reference Length | 1300 (m) |

| Reference Weight | 188 (kg) |

| Width | 1000 (mm) |

|

Items |

Unit |

Value |

Test Method |

| Basis Weight | g/m2 | 145 |

GB/T451.2-2002 |

| Tensile Strength(MD) | N/cm | 61.7 |

GB/T12914-2008 |

|

Tensile Strength(CD) |

N/cm |

45 |

|

| Elongation(MD) | % |

1.7 |

|

| Elongation(CD) | % |

2.0 |

|

| Elmendorf tear strength(MD) | N |

3.5 |

GB/T455-2002 |

|

Elmendorf tear strength(CD) |

N |

4.5 |

|

| Breakdown voltage | kV |

15 |

|

| Dielectric Strength | kV/mm | 12 | GB/T 1408.1-2006 |

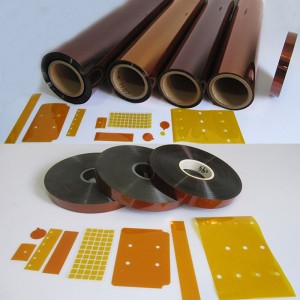

Application:

Aramid Paper is primarily used to create a lightweight, flame retardant impact-resistant, high-strength, and aging-resistant structure, making it ideal for aerospace, automotive, and military applications. It is used more and more widely in the fields of safety protection, high-temperature filtration, electrical insulation, structural materials, etc., and its popularity is increasing. It has become an indispensable and important basic material in many fields such as military, industry, and science and technology.

Application Industries:

1. Aerospace: Used in the manufacturing of honeycomb core materials for aircraft and spacecraft to reduce weight and enhance strength.

2. Automotive Industry: Used in high-performance vehicles to reduce weight and improve crash safety.

3. Military: Applied in protective equipment, military ships, and other military structures, taking advantage of its impact resistance and bulletproof properties.