Film is usually used as substrate then coated with single or double sided adhesive, general films are known as polyimide film, PTFE Film, PET Film , PE film, MOPP Film, PVC Film, etc.

Polyimide film and PTFE film are mainly used for high temperature working environment in electrical&electronic industry, and PET/PE/PVC/MOPP films are mainly used to protect the product from scratches and contamination during transport, processing, stamping, Shapes and storage etc, which is usually apply in processing or transportation protection for automotive industry, construction industry, Appliance&housing industry, electronic industry.

-

PET Films with Glass Fiber Composited MGM Insulation Material for Electrical Motors and Transformer

MGM insulation material consisted of three layers, F-class adhesive to adhere the two sides of glassfiber cloth with polyester film. MGM insulation laminates with excellet mechanical strength, great electrical properties and good flexibility. The polyester film provides electrical insulation and mechanical strength, then fiberglass cloth enhances the mechanical strength and heat resistance of the material. The adhesive used is insulating and fire-resistant. MGM is used for slot insulation, liner insulation, interlayerinsulation of motor, transformer or other electrical appliance. We have various thickness for customers, vary from 0.13mm to 0.25mm, and regular master roll width is 1000mm. We could also customized small size width for customers as per requests.

-

Energy Saving Aluminium Foil Insulation Mirror Reflection Film for Underfloor Heating

Aluminium Floor Heating Reflective Film is as light & bright as mirrors on both sides. It is made of two PET Protective Layers and one Reak aluminium reflective layer in middle, and it ensures the inside fragile aluminium plating layer’s performance and can ensure the life of aluminium plating layer. The shelf life of this film is more than 50 years, the same as the building’s. What’s more, with the material’s mirror reflectivity of more than 98%, it improves heat reflection and radiation capabilities to ensure constant indoor temperature and save a lot of energy and cost.

-

Comprehensive Performance PET Film for Thermal Transfer and Printing Industries

PET Film(Polyester Film) is a relatively comprehensive film with excellent physical properties, such as good transparency, glossiness, and dimensional stability. It also has excellent chemical properties, such as excellent mechanical properties. Its strength and toughness are the best among all thermoplastic plastics. Its tensile strength and impact strength are much higher than ordinary films. It also has excellent heat resistance, cold resistance and good chemical and oil resistance. It can be widely used in thermal transfer, printing, photosensitive materials, electronics, electrical insulation, industrial film, packaging decoration, screen protection, optical grade mirror surface protection and other fields.

-

Tesa 50530 Alternative White Protective Film for Freshly Painted Surfaces on Cars

Our White Protective Film is combines polyolefinic film modified UV-resistant material with pressure-sensitive adhesive. The product has good adhesion properties and the glue has excellent weather resistance. It is the best protection solution for freshly painted car bodies. Applied after the painting process, the white protective film provides reliable protection for painted surfaces susceptible to damage. Suitable for the protection of smooth surfaces inside and outside of the car, such as smooth surfaces and logos on the outside of the car, high-gloss surfaces and screens on the interior of the car. It is an ideal choice to replace tesa 50530, 50560 and 50535.

-

High Temp Polyether Ether Ketone (PEEK ) Film Material for Engineering Applications

Polyether ether ketone (PEEK) Film is a polymer created by step-growth polymerization, in which the polymer chain doubles with each polymerization step.

This material boasts incredible electrical resistance along with heat resistance, wear resistance, and fatigue resistance. PEEK is also creep-resistant, meaning it will retain its shape in harsh environments and high temperatures, and when placed under mechanical stress. Along with being tough, PEEK is lightweight and easy to manufacture.

Our PEEK material adopts the patented technology, in the aprotic polar solvent, diphenylsulfone is used as solvent, and 4,4′-difluorobenzophenone and hydroquinone are used as monomers. In the presence of an alkali metal carbonate, it is formed by polycondensation at a high temperature. During the polymerization, the purpose of controlling the molecular weight of PEEk is achieved by controlling the viscosityof the polymerization.

In order to meet the various needs of customers, we will modify PEEK, adding carbon fiber, glass fiber and other reinforcing materials to improve the mechanical properties of PEEK: adding PTFE, molvbdenum disulfide.etc, to improve the self-ubricatina ability of PEEK, and then improve wear resistance; add titanium dioxide, zirconium dioxide, etc. to improve mechanical rigidity and ensure electrical performance. In addition, in order to meet customer needs, we can provide white, black, yellow, green and other color PEEK particles.

-

Heat Curable Adhesive Bonding Sheets for FPC board or Stiffeners

Heat Curable Adhesive Bonding Sheets is also known as sheet adhesive, FPC bonding sheet or pure adhesive, which uses modified acrylic adhesive coated on release paper directly. Our adhesive bonding sheet uses flame retardant modified acrylic adhesive which has excellent bonding strength and able to withstand multiple lamination cycles. It’s equivalent to Dupont Pyralux® FR Sheet Adhesive. And it’s mainly used to bond flexible circuit to rigid flex boards, bond the PI stiffeners, or steel sheets etc,. Our adhesive bonding sheet is complied to REACH, ROHS and UL Certificated. The regular thickness is 12um, 15um, 25um, 40um, 50um.

-

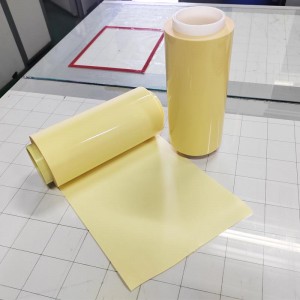

Silicone Oil Coated Polyester Release Film for Adhesive Tape Die Cutting&Lamination

Silicone coated Polyester Release Film is designed for use as a release liner in pressure sensitive adhesive application. It’s usually named as peel film, release film or release liner, which uses polyester film as carrier film and single side or double side coated with silicone oil to decrease the absorption force from the adhesive side and achieve release effect from adhesive tapes.

The polyester release film can be divided by different release forces: light release film, medium force release film and heave force release film. Besides of that, we can provide various thickness ranges from 12um, 19um, 25um, 38um, 50um, 75um, 100um, 125um, etc to meet different application.

-

Low Adhesion Single Side Polypropylene Film Battery Pack Tape for Lithium Protection

Our Battery pack tape uses special Polypropylene film as carrier then coated with low adhesion acrylic adhesive for lithium battery protection. It features with high temperature resistance to 130℃, and it can be peeled off without residue and pollution to the battery surface. It’s not only used to pack the power battery to provide protection during transportation but also provide protection during the bar code printing on the battery cell.

Our color is available in blue and transparent, and we can provide both material in rolls and die cutting custom sizes as per client’s application.

-

Low Adhesion Thermal Expansion Lithium Battery Tape for Core&Shell Protection

Thermal expansion Lithium Battery Tape uses special resin film as carrier and coated with very low adhesion acrylic adhesive. The tape is very thin and flexible, it’s usually used to fix between the lithium battery cell and shell to provide shock absorption protection for power battery. The tape thickness and volume would be increased after immersed by electrolyte bath, meanwhile, the battery’s volume and internal resistance keep no change. It’s widely used on the process of cylindrical lithium battery to protect and fix the battery core and shell during liquid injection.

-

Polyimide Aerogel Thin Film for Electronic Devices Heat Insulation

Polyimide aerogel film uses polyimide as carrier and specially treated nano aerogel on the polyimide film. Compared with polyester aerogel film, our polyimide aerogel film features higher temperature resistance and electrical insulation, and it can resist to higher temperature around 260℃-300℃, which provides excellent heat insulation function during the processing of manufacturing electronic components.

Our polyimide aerogel film has very low thermal conductivity and heat insulation features, which can solve the problem of heat equalization of consumer products in a small space, and provide heat insulation protection for the weak heat-resistant components. Besides, it can also control and change the direction of heat conduction to improve performance and shelf life of the products.

-

Strong Adhesion Acrylic Adhesive Polyester EV Battery Tape for Housing Protection

Our Electric Vehicle(EV) Battery Tape is a type of double layers polyester film tape, which uses two layers of special polyester films as carrier and coated with strong adhesion acrylic adhesive. It features with friction resistance, high insulation and voltage resistance properties, and also very easy to peel off without residue and pollution to battery surface. It’s not only used to pack the power battery to provide protection during transportation but also used as an insulation protection during the processing and assembly of EV power battery.

Our color is available with blue and black, and we can provide both material in rolls and die cutting custom size according to client’s application.

-

High Class Insulation JP Formable Polyimide film for Lithium Battery Gasket Insulation

JP Formable Polyimide Film is a new researched high class insulation PI film with thickness of 25um, 38um, 50um, 75um, 100um, and 125um for options. It can be heat and pressure formed as any 3D shape without shrinkage, and the forming pressure should be around 1MP(10kgs), and best forming temperature reach between 320℃-340℃. After forming, the polyimide film still has very excellent performance with the physical, chemical, and mechanical properties. It can be used to formed as gasket insulation shape for lithium battery, or diaphragms for automotive and heating sensors and switches, other electronic components that need formable gasket insulation like speaker cones, domes, spiders, and surrounds, etc,.