Features:

1. 0.03-0.2mm thickness for choice

2. Non-Stick

3. Ultraviolet Ray Transmittance: >95%

4. Fully fluorinated like PTFE

5. High temperature and low temperature resistance

6. Flame resistance

7. Weather and ageing resistance

8. Chemical solvent resistance and Anti-corrosion

9. Low Friction

10. High class Electrical insulation

11. Excellent smooth surface

Application:

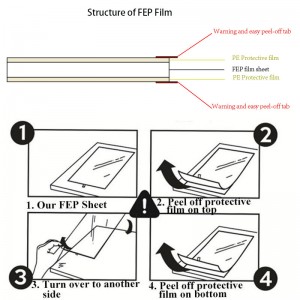

With the increasing of usage times, the FEP films would become bend, deform or perforate during printing or operation of 3D printer, then it needs to replace new FEP Film. It’s very easy to replace a new FEP Film. Firstly just to take your resin vat out, and clean out all the resin then unscrew the FEP film off the metal frames from the resin tank. Then take a new FEP Film, and peel off two sides PE Protective film and carefully place the new FEP between the two metal frames, put the screws in to secure it, cut off the excess FEP, and tighten it to a good level.

Besides of that, with the features of high transmittance, low friction and temperature resistance, FEP film is not only apply to the 3D printer, but also to other industry like electric iron board producing, copper board inner adhibiting,etc.

Below are some general industry for FEP FILM:

DLP/SLA 3D printer

Electric iron board producing

Transmission belt combining adhibiting

Copper board inner adhibiting

Explosion proof motor

Non-metal compensator in thermo-eletric plant