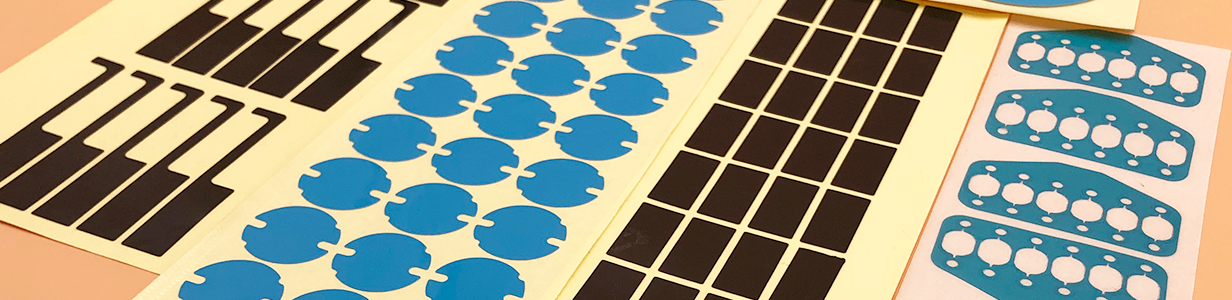

With more than 20 years experience in adhesive tape industry, GBS has been very skilled in providing different die cutting solutions. Die-cutting is one of our core business,We have different type of of die-cutting machine to produce custom die-cut tape components for various industries and applications,from simple shapes and sizes to complex material constructions and presentations.

-

Mica Plates for Thermal Electrical Insulation in Appliances and Power Systems

Muscovite or Phlogopite Mica Plates are premium insulating laminates consisting of approximately 90% natural mica paper and about 10% high-temperature silicone resin, hot-pressed into rigid or flexible sheets. These mica plates provide exceptional electrical insulation and dielectric strength, along with excellent thermal resistance ranging from 500℃ to 1000℃, while maintaining mechanical strength and dimensional stability under thermal cycling or mechanical stress. The material also features low thermal conductivity, outstanding flame resistance, and stable chemical properties. It can be precisely machined into custom components such as gaskets, washers, heater-element supports, slot wedges, insulating spacers, and other structural insulation parts. Available in a wide range of thicknesses (from 0.1 mm to over 50 mm) and fully customizable in size, these mica plates are widely used in electric motor and generator insulation, transformers, high-voltage switchgear, household and industrial heating appliances, furnaces and metallurgical equipment, high-temperature sealing and gasket systems, and various thermal barrier or fire-resistant applications.

-

Ultra-thin Matte Black Graphite PET Film Tape Electronic Insulation&Light Blocking

The Ultra-thin Matte Black Graphite PET Film Tape is designed for demanding electronic and optical assemblies that require an extremely thin profile, high bonding performance and a premium matte-black appearance. It incorporates an ultra-thin PET (polyester) film carrier—available from 2 µm to 12.5 µm—with a matte black ink coating on one side and an optical-grade acrylic adhesive layer on the other, protected by a release liner.

The matte black coating provides outstanding light-blocking and anti-reflection performance, while also offering scratch resistance and anti-fingerprint properties. These characteristics make the tape particularly suitable for back-light units, camera modules, sensors and other precision optical components, where controlling stray light and maintaining a clean surface are essential. Moreover, the optical-grade acrylic adhesive delivers high initial tack, strong adhesion to substrates such as PET, polyimide, metal foils, graphite sheets and ferrite absorbers, and maintains long-term stability under thermal and environmental stress.

Overall, this tape offers a well-balanced combination of an ultra-thin form factor, matte-black optical aesthetics, strong adhesion and durable environmental performance, making it an excellent choice for modern electronic, display and optical-shielding assemblies that demand both functional reliability and cosmetic quality.

-

Black Graphene Thermal Conductive Film for Electronics Heat Dissipation

Graphene Thermal Conductive Film is a high-performance thermal management material with ultra-high thermal conductivity (up to 2000W/(m·K)), excellent flexibility, and ultra-thin design. Made from graphene’s unique two-dimensional honeycomb lattice structure, it efficiently dissipates heat in electronic devices, new energy vehicles, 5G base stations, and AI servers. Its lightweight and bendable properties support the miniaturization and high-performance upgrade of products, solving core heat dissipation challenges for advanced technology applications.

-

Sabic Lexan FR700 Black Flame Retardant PC Film for Electrical Insulation

SABIC Lexan FR700, also known as POLYVANTIS, (formally known as SABIC Innovative Plastics) FR700, is a black polycarbonate film, with one side fine matte, and one side velvet. It features High-performance halogen-free flame-retardant with UL94 V-0/VTM-0 certification, designed for superior electrical insulation, EMI/RFI shielding laminates, and fire safety. Boasting exceptional dielectric strength (66kV/mm), wide operating temperature range (-135°C to 130°C), and RoHS/REACH compliance, this tough polycarbonate film is ideal for PCB insulation, battery modules, automotive electronics, industrial equipment, and medical devices—delivering reliable protection in demanding environments.

-

Irreversible Color-Changing Water Damage Indicator Sticker for Electronics Use

Our Irreversible Color-Changing Water Damage Indicator Sticker is made from durable coated PET film with a high-performance acrylic pressure-sensitive adhesive, ensuring long-term adhesion to metal, plastic, or painted surfaces, featuring strong stickiness, anti-ultraviolet properties, and anti-counterfeit capabilities.

Before exposure to water, the label appears white. Once it comes into contact with liquid, the detection area permanently turns red, providing unmistakable proof of water ingress or humidity exposure. This irreversible color change prevents tampering and ensures reliable results for warranty inspection, quality control, and after-sales evaluation.

These labels are widely used in electronics manufacturing, mobile devices, battery packs, and consumer electronics to identify potential water damage or seal failure during use, storage, or transportation.

-

High Performance Cloth Duct Tape Dots for Temporary Fixation

GBS Cloth Duct Tape Dots are pressure-sensitive adhesive tapes with a cloth backing coated with polyethylene. We also offer customization in various sizes and colors according to customer requirements. The cloth backing provides strong tensile strength and abrasion resistance, while the adhesive offers high tack and leaves no residue upon removal. These tape dots are widely used for temporary attachment and securing cables on stage floors, podiums, or other surfaces to ensure safety or concealment.

-

Flexible Sintered Ferrite Sheets for NFC and RFID Communication Systems

Flexible Sintered Ferrite Sheets is a kind of excellent sheet materials used in 13.56 MHz communication magnetic field around antenna for anti metal, and it provides high permeability and low losses. The flexible ferrite sheets feature easy-to-apply adhesive mounting tape. It is ideal for improving the efficiency of wireless power transfer (Qi-WPC, PMA, A4WP, WCT), improving the performance of NFC and RFID communication systems. Additional applications include EMI suppression and magnetic shielding.

OEM die cutting service provided as per customers’ requests.

-

Highly Resistant Against Chemicals Tesa 6930 Laser Label Tape Laser Engraving and Cutting

Tesa 6930 Laser-Label Tape is a double layer, brittle acrylic film, which makes it possible to realize any desirable label variation and format using only one material. Because of its characteristics of being highly resistant against chemicals, abrasion, temperature and ageing, it ensures that the function of anti-tampering labels can be realized throughout the entire life cycle of the product, while carrying information and achieving intelligent process control.

-

High Temp Polyether Ether Ketone (PEEK ) Film Material for Engineering Applications

Polyether ether ketone (PEEK) Film is a polymer created by step-growth polymerization, in which the polymer chain doubles with each polymerization step.

This material boasts incredible electrical resistance along with heat resistance, wear resistance, and fatigue resistance. PEEK is also creep-resistant, meaning it will retain its shape in harsh environments and high temperatures, and when placed under mechanical stress. Along with being tough, PEEK is lightweight and easy to manufacture.

Our PEEK material adopts the patented technology, in the aprotic polar solvent, diphenylsulfone is used as solvent, and 4,4′-difluorobenzophenone and hydroquinone are used as monomers. In the presence of an alkali metal carbonate, it is formed by polycondensation at a high temperature. During the polymerization, the purpose of controlling the molecular weight of PEEk is achieved by controlling the viscosityof the polymerization.

In order to meet the various needs of customers, we will modify PEEK, adding carbon fiber, glass fiber and other reinforcing materials to improve the mechanical properties of PEEK: adding PTFE, molvbdenum disulfide.etc, to improve the self-ubricatina ability of PEEK, and then improve wear resistance; add titanium dioxide, zirconium dioxide, etc. to improve mechanical rigidity and ensure electrical performance. In addition, in order to meet customer needs, we can provide white, black, yellow, green and other color PEEK particles.

-

Rogers Bisco HT-6000 Solid Silicone for Gasketing and Sealing

Rogers Bisco HT-6000 solid silicone series have very high performance in gasketing application. HT-6000 series has different grades of shore A Durometer from 10-65 for choice. HT-6210 is extra soft with 10 shore A Durometer, HT-6220 is soft grade with 20 shore A and HT-6135 is tight tolerance solid silicone, HT-6240 is transparent solid silicone and HT-6360 is firesafe grade solid silicone. The solid silicone materials provide low compression set (<5%), high tear strength, waterproof properties and extremely tight thickness tolerances, which is ideal as function of cushioning, sealing, gasketing, gap filling and shock absorption, also even as flame barrier in various industries, like automotive industry, electronic industry, etc.

-

Medium Firmness Silicone Foam Rogers Bisco HT-800

As a family member of Rogers Bisco Silicone Foam Series, Bisco HT-800 is a type of medium firmness silicone foam. HT-800 has excellent memory and low stress relaxation which can reduce maintenance costs from gasket failures caused by compression set and softening. It has compact cell structure and has excellent property of UV, Ozone and extremely high temperature resistance. It also offers shock absorption and vibration isolation in electronic components. It can be laminated with 3M pressure sensitive adhesive tapes like 3M467/468MP, 3M9448A, 3M9495LE and custom die cut into different shapes and sizes. HT-800 silicone foam can be used as gasketing and sealing, gap filling and cushioning, shock absorption and vibration insolation in various industries like electronic components assemble, automotive manufacturing and assemble, LCD Display protection etc.

-

Custom Converting Full Series of Foam Tape Rogers Poron 4701/4790 Series

As a professional adhesive tape converter, GBS is not only manufacturing our own brand adhesive tape, but also providing converting services for other brand materials, and Rogers Poron material is included. Rogers Poron has various different series of Polyurethane foam with different thickness, different grades of hardness with different functions and applications. We can provide both log roll materials for Poron material but also other sheets with precision die cutting services according to client’s drawing and application.