Features:

1. Good shear resistance

2. Soldering resistance temperature is 288℃

3. Excellent chemical stability ,

4. Radiation resistance,

5. Chemical solvent resistance and anti-corrosion

6. Easy to die-cut in any custom shape design

7. High class electrical insulation

8. Thermosetting adhesive

9. Smooth finish, no bubbles and delamination

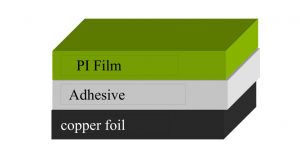

FPC flexible circuit board is usually bonded with thermosetting adhesive film and polyimide stiffener plate. The thermosetting adhesive film is without viscosity while solid at normal temperature, but when the temperature rises to a certain range, it will change into a semi-solidified state with strong viscosity. At this time, FPC will stick to the polyimide stiffener plate. The general practice is to align the PI stiffener fit to a right position, and use the electric soldering iron for 1~2 seconds to fix the single point position. After high temperature and high pressing, the whole surface would be completely bonding, then baking the film to cure the adhesive.

The processing condition of copper clad polyimide film or polyimide stiffener sheet:

1. The first band: temperature 120℃, high pressure 20kg/ cm², 1min;

2. The second band: temperature 140℃, high pressure 30kg/ cm², 80min;

3. The third band: temperature 80℃,high pressure 30kg/ cm², 5min;

Application:

FPC board assembly

PCB Board manufacturing

Coverlay or Stiffener in F-PCB.

Automotive circuit board assembly

Transformer and Motor Insulation.