3M8673 Thermoplastic Polyurethane Protective Tape for Erosion Protection

Features

- Offers a complete range of foam densities providing excellent print quality from process to combination to solid printing.

- Consistent caliper control allows the printer to use multiple foam densities on a print job to optimize print quality.

- Use the 3M proprietary Easy Mount liner, creating micro-channels in both adhesive surfaces.

- The crosshatched pattern creates a continuous and permanent network of micro-channels in the adhesive, allowing air to escape from between the tape and cylinder/sleeve and between the tape and plate.

| Adhesive Type | Differential Acrylate |

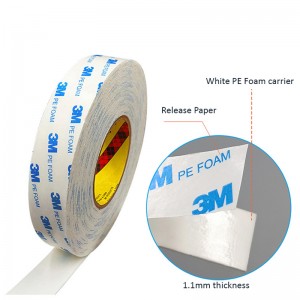

| Backing (Carrier) Material | Medium Soft Polyethylene Foam |

| Primary Liner | Polycoated Polyester |

| Film Thickness | 0.114 mm |

| Application Thickness | 0.508 mm |

| Total Tape Thickness | 0.559 mm |

| Product Color | Yellow |

| Roll Size | 50.8mm-1371.6mm*22.9m |

| Density | 433kg/m³(27 lb/ft³) |

| Compression Deflection: 10% Compression | 49 kPa |

Application Industries:

3M flexographic plate mounting tapes are highly engineered to provide very tight caliper tolerance to allow printers to use tape from different manufacturing lots and keep tight print registration. The compressible foam will withstand long and high speed print runs.

This is manufactured for 20 mil applications. It is constructed with engineered acrylic adhesives. The adhesive on the linered (plate) side of the tape is designed for mounting of photopolymer plates. The adhesive on the non-linered (sleeve/cylinder) side is designed for mounting to flexographic printing cylinders or sleeves, providing easy application at mounting and clean removal when demounting.

- Mounting photopolymer plates to flexographic printing cylinders and sleeves

- Used in combination, process and solid printing processes

- 3M sticky back tapes are designed for wide-web presses to print film or paper for flexible packaging industry